As concrete ages, surface stresses, delamination, undermined expansion joints and other problems can occur. C²'s liquid hardeners/thickeners, combined with our customized grinding and polishing technique, can remove the top layer of old concrete and strengthen the floor, increasing its resistance to impact and abrasion.

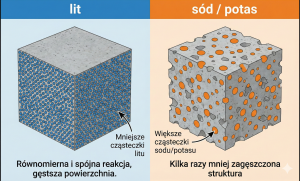

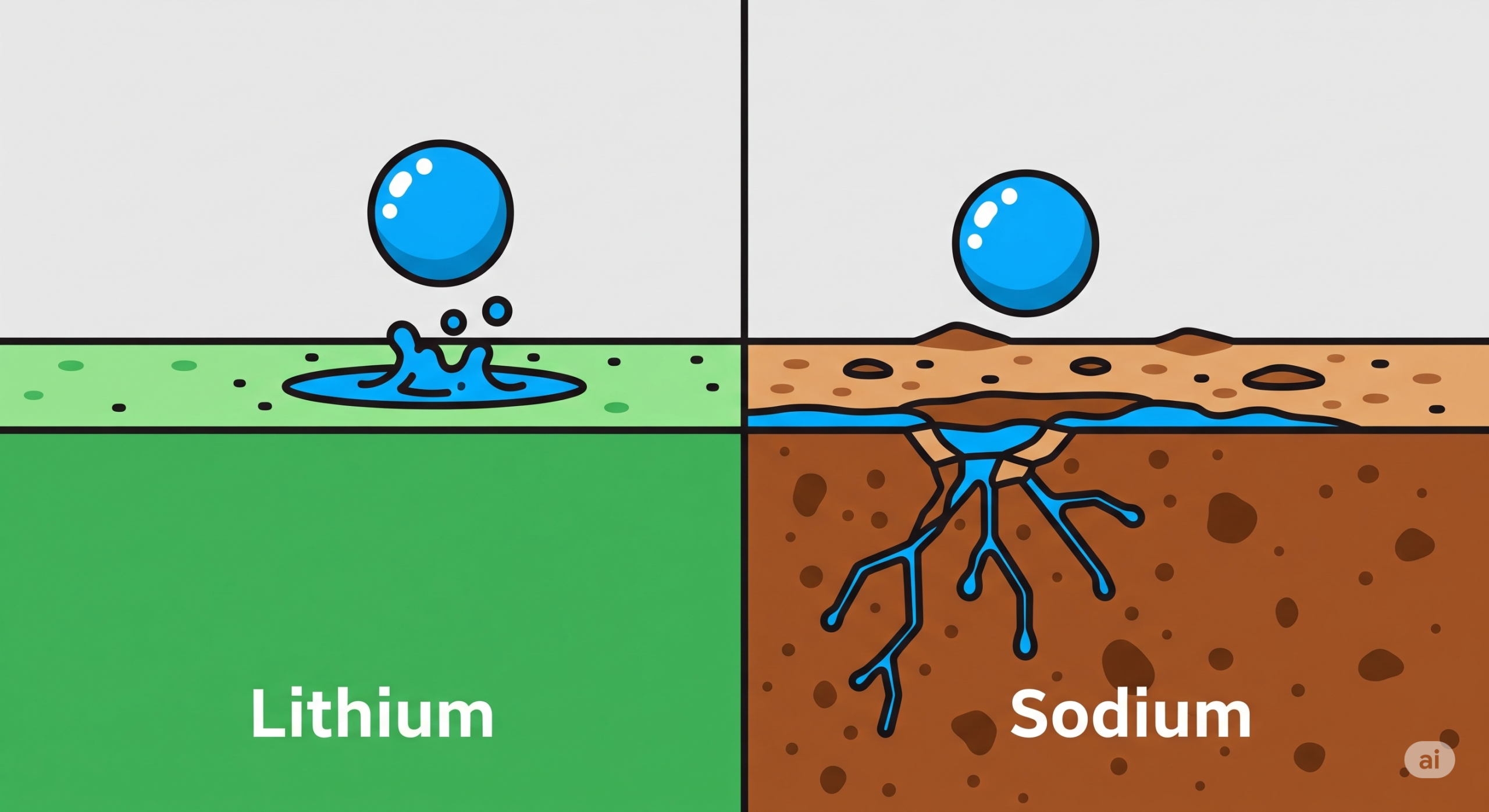

Crete Colors Polska's lithium hardeners prevent or reduce alkali silica reactivity (ASR).

Crete Colors Polska's lithium hardeners prevent or reduce alkali silica reactivity (ASR).